We are a precision tooling manufacturing firm established in 1974. Our core business is the design and construction of cutting and forming dies for metal sheet, with special attention to the packaging world. Up to date technology, use of innovative materials, a versatile structure, and a high quality standard allowed us to grow and make a name in both and foreign markets, as suppliers of complete tools and spare parts.

Micromec firmly believes that these attitudes and values, pursued over time and shared with other companies, allow to enrich the company with an immaterial capital consisting of relationships of esteem and trust within the company and with customers, suppliers and public administration, able to “infect” and promote real economic development, on a human scale, less subject to the variability and whims of the market.

Our quality system is certified ISO 9001:2008

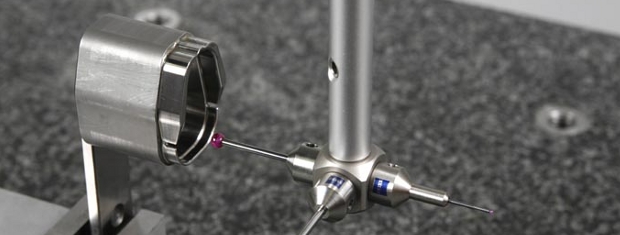

The necessity to satisfy high quality standards, easily documentable, has led Micromec to invest in the metrology department.

We monitor the temperature and the humidity of the metrology room 7/7 days for 24 h a day to maintained them uniform.

Actually our metrology room is equipped with proper (adequate) instruments from the simple manual micrometer to the recent CMM Zeiss UPMC 850 CARAT, that we use to control (check) 100% of our products.

All the instruments, that are periodically inspected, place Micromec among the leader companies of the industry.

The metrology room is managed by highly specialized personnel regularly trained and updated as per Micromec tradition.

The vivacity of the actual market and the changeable needs of the clients makes Micromec technical department a strategic area of the company.

The young, dynamic and highly qualified personnel, is always ready to reply to the requests that our clients submit to us daily. Our staff is constantly engaged in new dies engineering, from the development of the product to the realization of the final die; we support and assist our clients from the feasibility to the final inspection.

All the activity are supported by last generation CAD/CAM software that are regularly updated.

At present the software that we use includes CAD 2D/3D systems. For a complete technical support and cooperation (collaboration) with our clients we are able to manage all CAD/CAM 2D/3D main formats as DWG, DXF, STEP, IGES

© copyright 2020 – All Rights Reserved

Credits – Web al Chilo –